Sometime last fall, the Library Society’s Curator and Historian Debbie Fenn showed me a letter from October of 1960 written by Hannah French and addressed to Virginia Rugheimer, then a librarian at the Library Society. In her letter, Hannah requested information ‘concerning binders at work in Charleston up to the year 1820,’* with the intent of eventually including this information in her 1986 publication Bookbinding in Early America (this is confirmed in a letter from 1976 that Debbie came across about a month ago). From what I’ve been able to gather, and from the fact that no Charleston binders are featured in her book, Hannah’s inquiries did not result in anything substantial enough to include.

Inspired by this correspondence, and the fact that the Charleston Library Society is the second oldest circulating library in the country with some decent colonial holdings (it’s not all the Civil War here), sometime last fall I began searching through our card catalog for early South Carolina imprints in the hopes of digging up some early South Carolina bindings. Well, needless to say things got off to a promising start, with a ticketed binding[1]:

Upper cover of A Compendium of Latin Grammar, 1795. Measures 18.0 (H) x 11.3

x 1.5 (T) cm

Spine of A Compendium of Latin Grammar, 1795.

And on the inside of the front cover, a glorious, though far from golden, binder’s ticket:

Ticket Measures 6.7  x 4.6 (H) cm

x 4.6 (H) cm

Despite its significance as one of the only pre-1800 ticketed Charleston bindings currently known, and the fact that the ticket even tells us where David Bailey is originally from, there are so many things I love about this binding. Here is a short list:

- As the identity of the binder is made plain, many of the structural and decorative elements of the binding provide a baseline that will hopefully allow me (or other researchers) to identify other Bailey bindings.

- The funky bubble-feather helix roll used to tool the panels on the front and back cover. Who came up with that design?

- The little ‘palmetto tool’ impression on the spine, which served as the inspiration for this year’s Standards of Excellence Seminar logo.

This book, along with the short but steadily growing list of other pre-1820 Charleston bindings I’ve located thus far, will be featured in an article on early bookbinding in Charleston that I’m working on for a future volume of Suave Mechanicals (If you haven’t already checked them out, the first and second volumes, along with pretty much everything the Legacy Press publishes, are incredible). I’m sure I’ll be posting a lot more about this project as it progresses – apologies in advance!

+++++++

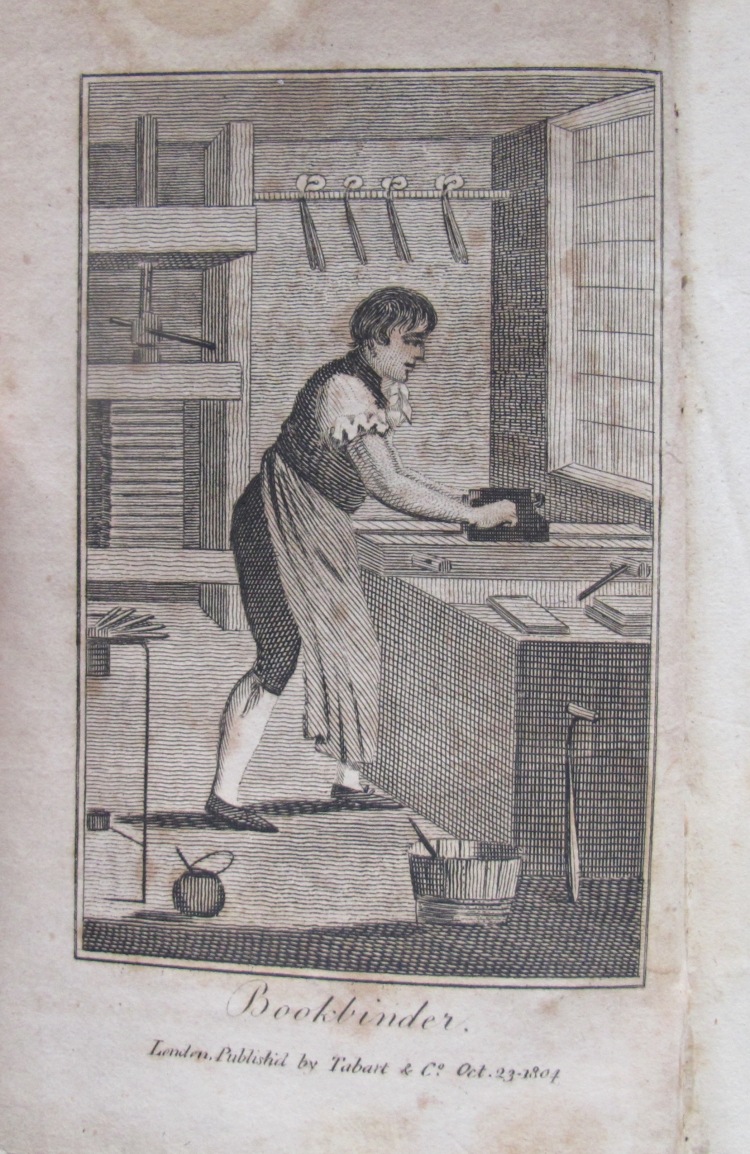

*1820, though seemingly an arbitrary cutoff, represents the a huge nail in the coffin of the small craft binderies in the days of yore where every step of the process was done by hand, because shortly thereafter in 1827 William Burn invented the first true machine used in bookbinding: the rolling press. Over the next 80 years or so following this invention, virtually every aspect of bookbinding was mechanized and the once-small workshops replaced by large-scale factories.

[1] Mills, Thomas. A Compendium of Latin Grammar. Charleston: Timothy & Mason, 1795. Print.

The sturdiness and flexibility of the bone, ergonomic handle and 13 degree bevel angle all make it ideal for various lifting and scraping operations. Already I’ve used it to scrape a sale sticker off a desk lamp! I anticipate a revolution in the bone tool business very soon…

The sturdiness and flexibility of the bone, ergonomic handle and 13 degree bevel angle all make it ideal for various lifting and scraping operations. Already I’ve used it to scrape a sale sticker off a desk lamp! I anticipate a revolution in the bone tool business very soon…